According to Dell’Oro’s report, CoolIT Systems, Boyd, and Motivair were the top three earners in the Data Center Liquid Cooling arena in 2023.

After years of playing second fiddle to chilled air, it appears that direct-to-chip liquid cooling is finally going uptown. According to a report from market researcher Dell’Oro Group, the liquid cooling market for data centers has hit an inflection point and is going mainstream. In five years, the group said, expect it to be a market worth more than $15 billion.

“After tracking the Data Center Liquid Cooling market for five years, it’s finally transitioning from a niche technology deployed in specific segments of the market to mainstream applicability,” Lucas Beran, research director at Dell’Oro Group, said in a statement introducing a new Data Center Liquid Cooling research report that the organization released on Tuesday.

This is good news as far as I’m concerned. I’ve long been a proponent of direct-to-device liquid cooling.

Most data center equipment today is air-cooled, using chilled water to chill the area around the equipment, a wasteful process that generally accounts for more than 40% of a data center’s power consumption. That’s a lot, and although power consumption has always been a big issue for data centers, it’s recently become even more worrisome as data center power use has been on a sharp increase due to the increased demands of generative AI workloads.

This is a concern not only for the data center operators who must pay the bills, but for utilities that must reliably deliver the juice to keep them running. It also concerns environmentalists, who worry about pumping more carbon into the air during the era of climate change.

That being said, according to Beran neither cost cutting needs nor environmental concerns are behind the current increase in liquid cooling at data centers.

“Historically, liquid cooling vendors touted increased efficiency and sustainability as factors behind the technology’s adoption,” he said. “While those benefits remain true, it’s proved to be the increased thermal management performance capabilities, meeting the particularly demanding thermal requirements of high-end processors and accelerated servers, that is the current driving force behind its adoption.”

In other words, the move to liquid is being driven by the needs of the technology.

Liquid Cooling: A Technology in Flux

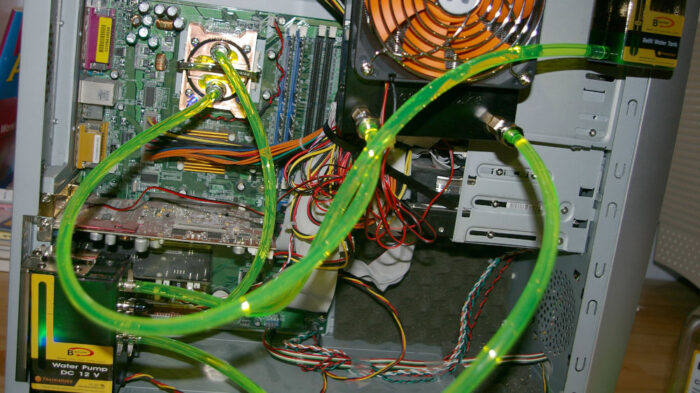

For the time being, single-phase direct-to-chip cooling, which pipes the coolant bath directly to a server’s components, seems to be leading the way. However, Beran indicates that might be because it’s the technology that has the head start.

“As this adoption occurs, it’s single-phase direct-to-chip liquid cooling deployments that are scaling first,” he said. “This is the result of long-standing adoption in the high-performance computing industry that has helped establish a more mature vendor ecosystem and end-user know-how to deploy and service the technology. Additionally, NVIDIA has specified single-phase DLC as the cooling technology to support its upcoming GB200 compute nodes.”

Beran said that two-phase direct-to-chip liquid cooling — which uses liquid with a low boiling point to add gas as a cooling component — and single-phase immersion cooling — in which the server is immersed in liquid — also show promise for market gains. Ironically two-phase immersion, which among other things requires no pumping equipment, so far seems to be a long shot.

“Both single-phase immersion and two-phase DLC are undergoing testing, validation, and proof of concept work, which is materializing in growing pipelines for those vendors. Two-phase immersion, on the other hand, is facing an uphill battle towards adoption, as it remains particularly challenged by the regulatory environment surrounding PFAS fluid use,” he said.

Christine Hall has been a journalist since 1971. In 2001, she began writing a weekly consumer computer column and started covering Linux and FOSS in 2002 after making the switch to GNU/Linux. Follow her on Twitter: @BrideOfLinux

I must admit to not having done the fluid dynamics and environmental math on this, but I fail to see how this affects “environmental impact” that much.

The chips produce heat as a by-product of the power used to make the chips work. That heat either goes off into the air directly through the use of heat sinks and fans that blow cool(er) air around the sinks and finally is carried out of the racks of boards by air conditioning that cools the entire room with the heat eventually being transferred to a heat exchanger that carries it to the outside.

The alternative is that the heat goes off into the liquid, which is then carried to a heat exchanger that carries it to the outside. The rest of the boards, with chips that produce less heat simply go into the room as above.

The heat has to go somewhere.

Various designs have tried to put the racks of systems into closed, air-conditioned spaces so the walkways between machines to not have to be cooled to a temperature lower than what humans like just to allow the CPU/GPUs (and the rest of the chips) to be cool. Sun Microsystems did a lot of work on this at one time.

One concept that could explain a savings is that with air-cooling the whole room has to be cold enough to allow the heat from the CPU/GPUs and all the other chips to be exchanged. This may require the room to be “supercooled”, which is bad.

The liquid-cooling might allow for “the other chips” to work in a higher temperature, since they do not generate as much heat as CPUs/GPUs.

Where liquid-cooling really shines is in tightly packed CPU/GPU situations where it is difficult to move enough air to cool those cnips using standard heat sinks and air-flow cooling. The liquid cooling can cool down the “hot spots” and allow tighter packing of these high-heat chips.

However, in the end there is a certain amount of heat generated and sooner or later, one way or another, it has to be dispelled into the atmosphere.

One way of really having an environmental impact is to use the heat to do work that otherwise would have to be done by some other energy source like acting as a heat pump to pre-heat water for other purposes, although a certain amount of that could be done with air-cooling too.

I would be happy to have someone point to where I am wrong.

It probably reduces the electrical impact by having less fans, duct work, and other things. Plus you don’t have to drop the temperature of the whole room to 60f to just to keep the CPUs/GPU running. You only are only collecting the heat directly from the source. Then the heat is vent directly outside instead of being harvest from inside the whole building.